Multiple Printed Circuit Board

Assembly Solutions

Are you looking for a printed circuit board assembly (PCBA) solution that offers small to very large volume build services? High mix and low or medium volume? Flex circuit assembly? A very low cost solution for simple assemblies? Integrity Sourcing Solutions represents multiple PCBA companies and can help you with any circuit board assembly project!

Are you looking for a printed circuit board assembly (PCBA) solution that offers small to very large volume build services? High mix and low or medium volume? Flex circuit assembly? A very low cost solution for simple assemblies? Integrity Sourcing Solutions represents multiple PCBA companies and can help you with any circuit board assembly project!

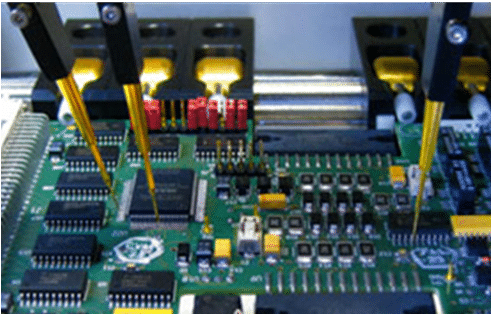

Our assembly solutions provide state-of-the-art Surface Mount Technology (SMT) assembly and Plated Thru Hole (PTH) assembly. Both leaded and lead-free processes are available.

We are committed to providing outstanding customer service and quality. Our highly qualified resources are focused on helping our customers succeed. Printed circuit board assemblies can be built to IPC-A-610 Class II or III depending on customer requirements.

We are committed to providing outstanding customer service and quality. Our highly qualified resources are focused on helping our customers succeed. Printed circuit board assemblies can be built to IPC-A-610 Class II or III depending on customer requirements.

All our solutions have multiple SMT lines. Some feature Dek Horizon screen printers with internal Hawkeye inspection, state-of-the-art Panasonic pick & place machines placing up to 75,000 parts per hour and Heller 10 zone air convection reflow ovens. Their SMT equipment will place the latest BGA (Ball Grid Array), Micro BGA, Land Grid Array (LGA), fine pitch leaded packages and components down to 01005 size. They provide BGA Part on Part (PoP) assembly with one BGA placed on top of another BGA, place micro spring pins and specialize in Flex Circuit assembly. For SMT inspection, many utilize a Nordson DAGE 5-Axis X-Ray machine with 0.5 micron feature recognition, critical for PoP inspections. They also employ Koh Young Technology and Mirtek Automated Optical Inspection (AOI) equipment for accurate and efficient inspections.

A large number of SMT component feeders are utilized in the SMT lines of all our providers. This allows them to have several jobs set up at a time for outstanding flexibility. Their equipment includes an advanced Feeder Exchange System (FES) for quick and efficient set-up and change-over of jobs.

In the PTH area, all are fully equipped to handle all types of through-hole components. All our solutions have extensive PTH assembly experience and capabilities supported by an array of component prep, wave solder, selective solder and PCBA cleaning equipment. Many have both a dedicated RoHS line and a dedicated leaded solder line. All their factories have been supporting PTH assembly for many years.

Whether you’re just starting your business or supporting a global customer base, our PCBA solutions have you covered. Whatever stage your business is at, they’ll take the time to understand your goals and find the right technologies to help you accomplish them. Get started with your project today by requesting a quote or by reaching out to us directly. We understand that manufacturing can get pretty complicated, which is why we’re always here to help.